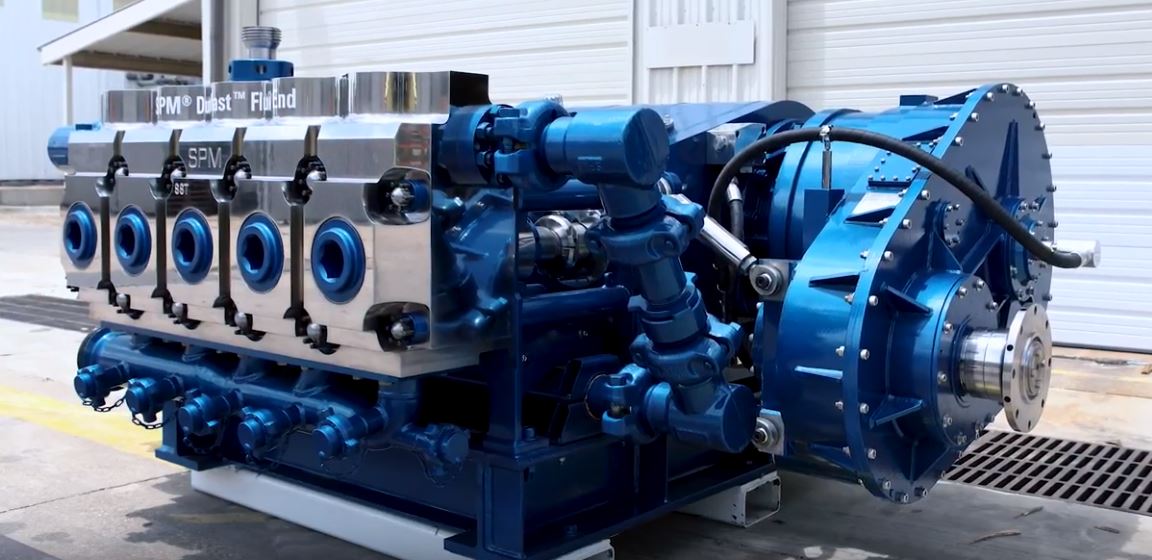

Fort Worth, Texas-based Weir Oil & Gas (Weir), Whatever conditions an operator is running legacy pumps in today, the SPM® QEM 3000 can run in similar conditions. Part of the company’s performance line of pumps, the SPM® QEM 3000 is expected to extend maintenance cycles by a factor of three as compared to what operators are achieving in similar service conditions currently. These enhancements dramatically affect their bottom lines, expanding traditional frac pump life span to improve uptime and productivity while reducing maintenance costs and total cost of ownership by at least 17 percent.

The SPM® QEM 3000 pump is an industry first and only gold standard, as it was purpose-built from the ground up and designed to withstand even the most punishing pressure pumping operations, including continuous duty, at a sustained maximum 275,000-pound rod load. In the Duvernay and Montney formations, the SPM® QEM 3000 pump operated 16-18 hours per day in temperatures averaging 20 to 23 degrees Fahrenheit at a frac pressure of 10,500 to 13,000 psi, average rod load of 206,250 to 233,750 psi with a five-inch plunger and a flow rate of 264 gpm to 343gpm.

Roller bearings looked like new after 3,200-hours and shell bearings had considerable life remaining. Other wear parts that would normally require replacement, such as guide sleeves, showed insignificant wear and did not require replacement. Moreover, Weir’s industry-first onboard filtration system delivered clean oil to enhance bearing life through optimized control.

While the traditional frac pump development process typically tests up to one million cycles, Weir completed an endurance test of its beta SPM® QEM 3000 in its Fort Worth Research & Development Center lasting three times longer than other pumps in the company’s history. A Calgary, Alberta-based customer is currently operating SPM® QEM 3000 pumps that have completed more than 10 million field cycles (approximately 1,700 hours) without any signs of fatigue to the main components at production sites throughout Western Canada.

“To achieve another milestone in the evolution of the SPM® QEM 3000 pump is an affirmation of the hard work and collaboration of so many,” said Bryan Wagner, Director of Engineering and Product Management, Pressure Pumping at Weir Oil & Gas. In throwing out the playbook on how a pump is designed, we are rewriting the rules on how it performs and how long it will last. As a result, our customer’s feedback to us is that they are realizing tremendous savings by reducing non-productive time and eliminating expensive parts replacement, support equipment, or pump rebuilds. We look forward to our continued collaboration and innovation on behalf of the industry.”

About Weir Oil & Gas

Weir Oil & Gas provides superior products and service solutions to make our customers more efficient and lower total cost of ownership.

More customers choose our pressure pumping solutions than any other. We provide well service & stimulation pumps, flow control products, replacement expendable parts and provide supporting engineered repair services. Weir’s Pressure Control solutions include wellheads, valves and frac trees, managed pressure drilling equipment including chokes, separators, & containment equipment. Globally we deliver engineered mechanical and rotating equipment repairs and upgrades, oilfield and drilling equipment repair and certification, rapid prototyping of spare parts, robust asset management and field engineering services.

About The Weir Group PLC

Weir Oil & Gas is part of The Weir Group PLC. Founded in 1871, Weir is one of the world’s most admired engineering businesses with 14,000 people operating in more than 70 countries. Discover more at www.global.weir.

Press Contact:

April Lynch, Pennebaker

april@pennebaker.com

Phone: 1+ 713-922-1895

One thought on “SPM® QEM 3000 Frac Pump continues to yield unsurpassed results”